Steering Wheel - TS-XW

I still stick to the original parts, it is no different in the case of the steering wheel. I thought for a long time about how to solve it. Which base should I choose? These were connected questions, because the method of installation, the price of the base, the quality and the effect of force had to be taken into account.

I thought about that I mount the servo base under the dashboard somhow, but then I have to buy a small but strong base, like Fanatec CSL DD.

| Ok, but it is expensive, and I only can use with its own dedicated wheels. I can print an adapter to able to use the wheel of car, but the DD doesnt work if it's not connected its electronic of own wheel. This can be eliminated, but then there is no wheel height adjuster and multifunction switches. In addition, the weight of the steering wheel of the car is three times that of the DD steering wheel. The downward load on the shaft would be too big |

So it is no more good idea to mount the base under dashboard. Rather I use the steering collumn with original wheel, mounting bracket, and switches. And there is the airbag clock spring what also a good part for work of horn. The collumn can hold the steering wheel, so only question is the inertial mass, since now not only that of the steering wheel, but also that of the column is added.

If I looking for cheaper racing wheel there is the products of Logitech G series, but that is lower category, and the force is too weak for this setup. And I'm also sure that the plastic shaft and gear would break quickly due to the inertial mass.

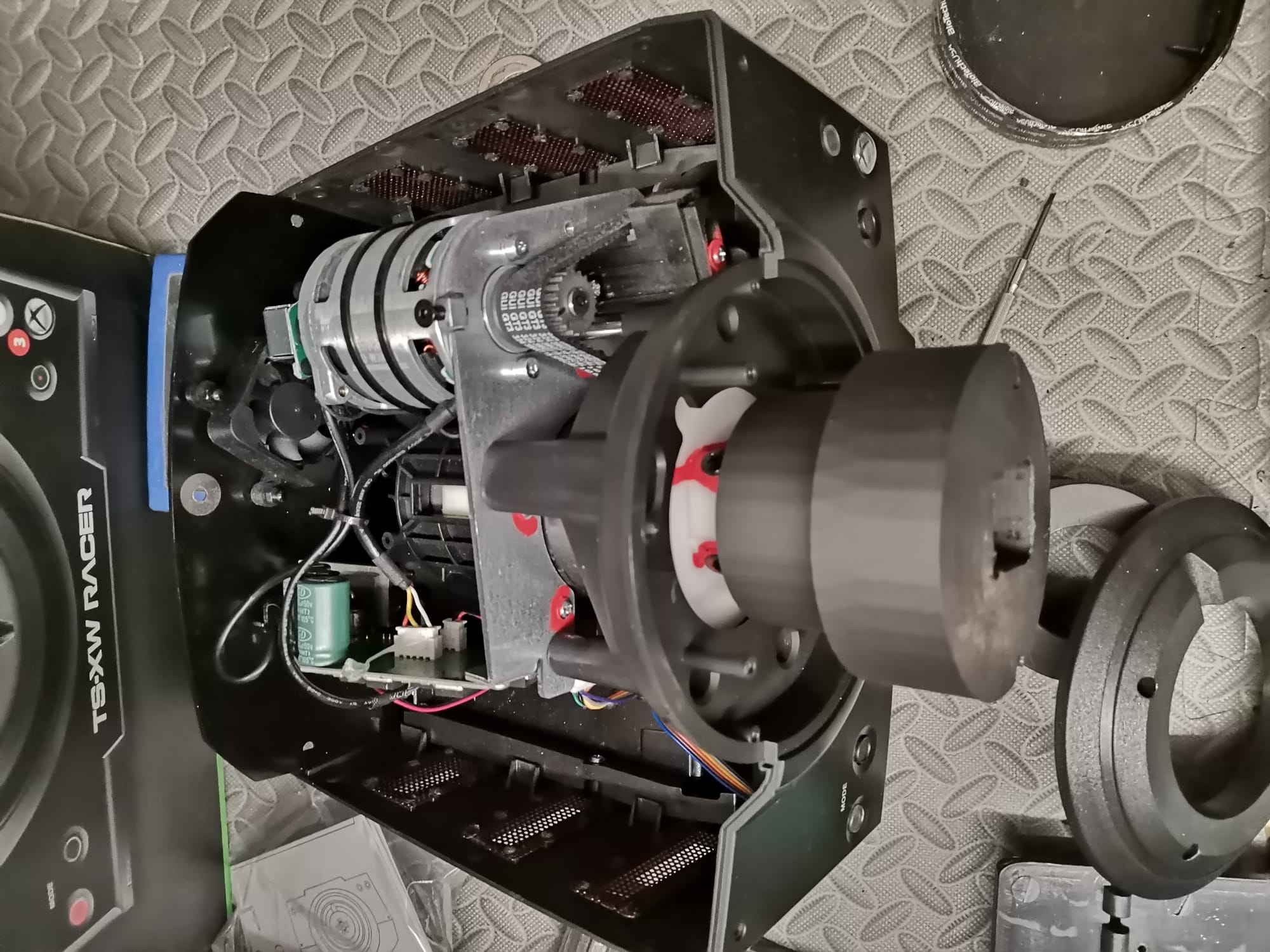

| After much thought I choosed a Thrustmaster TS-XW. It has not direct drive, it has belt. But has better price, and a good quality, with enough strength. The house is bigger than DD's and it has own cooling. |

Now I had to connect somehow the steering collumn with the servo base. Unfortunately there is not much free place between the wall and the car body, and I needed a little angle for nice fitting after the printed adapter was installed.

|  |  |  |

Maybe I oversized the adapter of base and collumn, but justified due to durability and load.

I made one steering collumn from two, because the original was short for this solution, and I couldn't connect with the base because its big body.

|  |

I hate the calibration of TS-XW, it spin so fast, so I have to remove the wheel before every calibration, or I fear it cracks the adapter, or the axis of the base.

But it is enough strong, it can twists my arm if I don't hold it strong when driving.

I mentioned the airbag clock spring. I used it to connect the horn and 2 extra buttons added to it to the PC via Arduino Micro.

At the same time I disassembled the pedalset I got with the base (T3PA), and built into the place of original pedals of car.